The following posts will cover a wide variety of topics relating to the body and exterior trim. I will start by discussing the closures and cut lines.

Closures are parts of the vehicle's body that open for access and close to complete the exterior shape. This includes the doors, hood, trunk lid, and sliding glass windows. In particular, closures need to provide access to the occupant compartment, engine bay, and cargo area. There are many ways to accomplish these objectives, which are introduced and explained below.

Lets start with the doors:

Front Hinged: Inexpensive and intuitive, this traditional layout is used in almost all cars. This requires a pillar in between the front and rear doors, called the B-pillar.

|

| Mercedes Concept Car |

Front and Rear Hinges: This setup is sometimes applied to vehicles with a small occupant compartment or wheelbase (distance between front and rear wheels) to reduce the length of the rear doors. Without, the B-pillar, access and foot-swing (aka leg room) are improved. It is also frequently used in high-end luxury vehicles. These are also referred to as suicide doors.

|

| Rolls Royce Ghost |

Scissor Doors: Not only do these doors add flair to exotic cars, but they come with some practical benefits. In tight parking spaces, wide sports cars with scissor doors will have easier ingress/egress (enter/exit) than out-swinging doors.

|

| Ferrari LaFerrari |

Gull Wing: This has similar advantages to the scissor doors. However, in the open position the doors add considerable height to the car, so it is mostly seen in low sports cars.

|

| Mercedes SLS |

Sliding Doors: These are used in minivans and commercial vans, where out swinging doors can be impractical. It is essential that the vehicle has enough room behind the door to Today they are usually electrically powered.

Now lets look at systems that provide access to the engine and cargo areas.

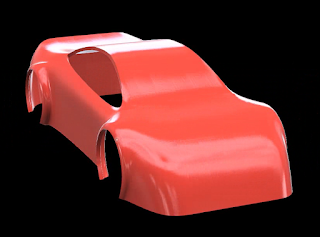

Access Covers: These are used in performance and race cars, where fast, easy access to the power train and suspension components is important. These covers have cut lines (the perimeter) on the side of the car, providing large apertures.

|

| Pagani Huayra (also has gull wing doors) |

Lift Gate (hatch): This is common for minivans, hatchbacks, and SUVs. They provide cover for the rain and won't interfere with traffic or nearby parked cars. Sometimes these are electric powered.

|

| Porsche Panamera |

Tailgate: This is mostly used on pickup trucks to extend the bed floor, and it can remain dropped when driving. Some are removable to assist in loading process.

|

| Ford F-150 |

Some vehicles combine the lift-gate and tail-gate.

Lift and Swing Gate: This is often used on vehicles that carry a spare tire on the rear gate. One example is the Hummer H3 (couldn't find picture).

Rear Swing Doors: These are often used in commercial vans. They are designed to swing at least 180 degrees to provide easy access from all angles.

|

| Ford Transit |

Hood and Trunk Lid: Most cars use this simple system for access to the engine and rear cargo.

|

| Pontiac Solstice |

Thanks for reading!